Engraving sound at Pier 9!

The Daily tous les jours creative team went to Pier 9 for a 2-week residency in preparation for the Market Street Prototyping Festival and I brought along a research idea: exploring the possibilities of storing music on surfaces. Asking if we can give objects a hidden layer of sounds that can be played by anyone, with any tool. Could we transform everyday street infrastructure into potential instruments or secret sound storage devices (similar to how greyworld hid “The Girl from Ipanema” on railings)?

What I had in mind would use a similar mechanism to a record player (phonograph) needle translating physical bumps on the vinyl surface into airwaves. I wanted to use the digital-fabrication goodness at Pier 9 to create engraved patterns on surfaces that can be turned into sounds mechanically. And instead of needing a special tool (=record needle) to play the sound, I wanted everyone to be able to “release the sound” with a pen, a fingernail or a coin.

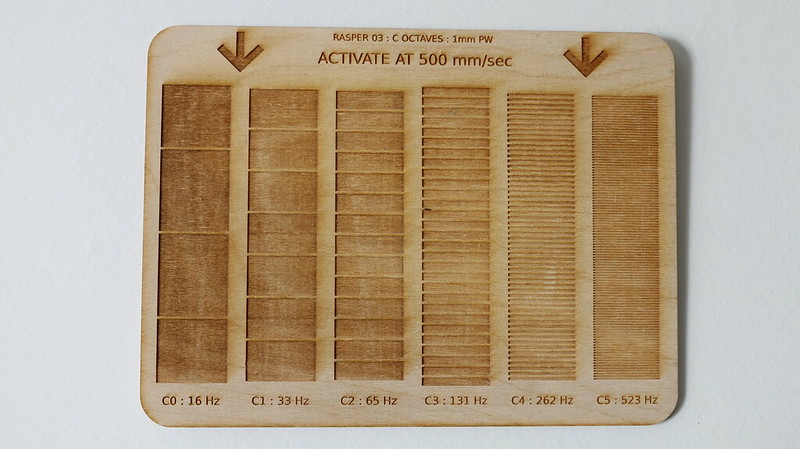

Engraving a regular pattern into a surface, and then running a stick alongside it, produces a certain pitch that is caused by the rate at which your stick bumps against the grooves of your pattern. If you run the stick alongside it a bit faster, it’ll hit the bumps faster and produce a higher pitch.

The instrument that gets closest to this idea is the Güiro / Rasps / Scraper / Raspel / Raspadora / Scratcher which usually consists of an engraved resonant body which you scrape along with a stick. But while these instruments are mainly used for creating “rasp” percussion effects, I wanted to explore their potential for pitch variation.

So I started with a bunch of pitch calculations. The C4 (Middle C) note emerges from something vibrating at ~262 oscillations per second. If we assume we can activate our engraved surface at a speed of 500 mm/sec (arm swiping speed), we’d have to position our engraved bumps at a distance of 1.9 mm each. An E4 demands a bump-distance of 1.5 mm, while a G4 calls for 1.3 mm. The math formula being: speed of activation / frequency of oscillation = distance between bumps.

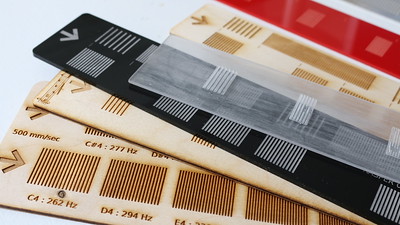

Then I turned to the machines and started lasering stuff! I worked mainly with acrylic and wood, on the Epilog 36EXT Lasercutter. After a first proof of concept that different groove patterns indeed produced different pitches, I turned to explore rhythms. Leaving larger gaps between “notes” also improved the sound perception, by giving the airwaves time to spread, without being interrupted by the instrument’s natural “raspiness”. Empty spaces are always important.

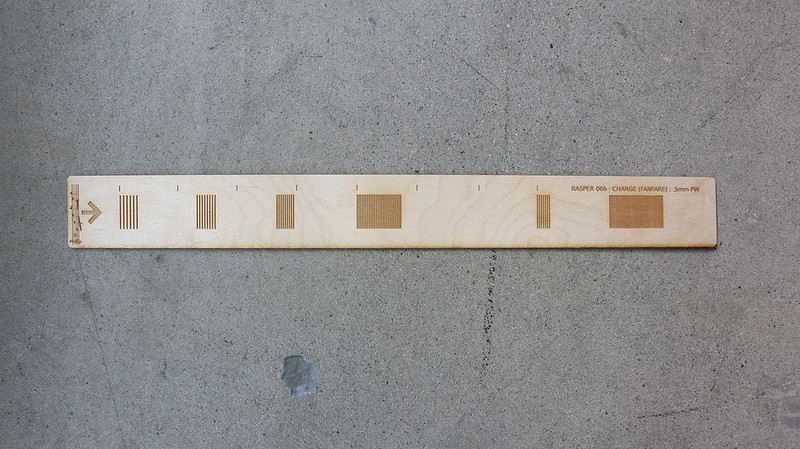

After having “mastered” pitch and rhythm, I turned to melodies. As I was limited in the length of boards I could laser-cut, the melody had to be short. And after spending way too much time trying to transcribe Kraftwerk’s The Robots base melody, I finally selected something that is short and well known. And – as it turns out – endlessly annoying for everyone around you: Charge (Fanfare).

The 6-note melody can be seen in musical notation above, and what it looks like translated to an engraving pattern on the right:

I then set out to test the same pattern on the different machines Pier 9 has to offer. Besides laser-engraving on acrylic and wood (working 2d with Inkscape), I printed a three-dimensional version on the Objet 500 Connex 3D printer (using OpenSCAD for some simple parametric .stl production) and cut a metal version with the Omax Waterjet 60120.

Now, please judge the auditory results for yourself: